Local Firm Creates World’s Largest Lunar Lab in Lacey

“Once you’ve landed on the Moon, that is not the best place to discover your equipment needs more testing,” quips Melissa Roth, one of the co-owners and lead researchers of Off Planet Research (OPR).

The surface of the Moon may not seem like a top business destination, but OPR’s founder, co-owner, and lead researcher Vince Roux said the private sector is leading the charge with at least 20 announced Moon missions in the next five years.

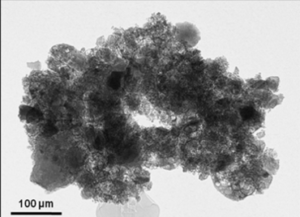

Upon arrival, the harsh environment degrades equipment made on Earth very quickly. Lunar dust is fine like powder, but also abrasive with microscopic sharp edges since there’s no wind or water to smooth it out. It clings to everything, causes machinery to seize up when it gets into moving parts and repeatedly wore through layers of astronauts’ Moon suits on Apollo missions.

“Our goal is to provide better testing down here on Earth so that the equipment is less likely to fail 239,000 miles away,” said Melissa.

A closeup view of some of the simulant already in the Lunar Surface Simulation Lab.

The particles may be small, but they can tear a rover apart! Photo Credit: Off Planet Research, LLC.

OPR rents their Lunar Surface Simulation Lab and lunar simulants to companies planning to send people or equipment to the Moon. This precise, pre-trip testing dramatically increases mission assurance, cost effectiveness, and speed of development of safe and effective space-based technologies.

Melissa gave a real-life example. “When a Chinese rover went to the Moon in 2013, it broke after 42 days because of the abrasive atmosphere. The camera on the rover continued transmitting, in one spot, for the next 29 months. Wouldn’t you want your equipment to last for years, not days, after you went to all the trouble of getting it to the Moon?” She said each additional day on the Moon can be worth millions of dollars.

“Some of the low-hanging fruit [for Moon-based businesses] includes rare earth elements for electronics, like titanium, and Moon ice to make rocket fuel,” said Vince, explaining all those pursuits require exploratory drilling. Vince also said for NASA to meet its mission of getting to Mars, they need to be able to obtain rocket fuel in orbit. “There are also contracts from private organizations waiting for the companies who can do that.”

OPR has had initial discussions with many firms who all need a reliable place to test the equipment they’ll be using on the Moon.

Might Your Firm be a Space Company?

“There are many companies in the Puget Sound that are space firms, and they just don’t know it yet,” said Vince at a regional economic development conference last December. What did he mean?

“There are many companies in the Puget Sound that are space firms, and they just don’t know it yet,” said Vince at a regional economic development conference last December. What did he mean?

“There are so many opportunities for growth and research,” said Vince.

He said Moon-adapted components, for inclusion on future lunar missions, will be needed in almost any industry. OPR’s lab can be a great testing location for those designing and fabricating equipment.

“As we were constructing our lab, we wondered about what would be the best seals for keeping the lunar environment in the lab,” said Vince. During the Apollo missions, it was extremely difficult to maintain a seal due to the abrasive nature of the Moon dust.

So, they called Kennedy Space Center’s Swamp Works, an organization with a mission of creating technologies for working and living on the Moon and other bodies. Their answer? “They said try a bunch of different things and see what works,” said Vince. “They told us we’re years ahead of others asking these questions and that in a couple years we will be the experts.”

The moral of the story? Thurston County can be full of experts in Moon-adapted equipment. Door sealers, memory boards, windows, fasteners, solar panels, filters, nuts, bolts, drive trains. Vince and Melissa see opportunities in all of them as businesses figure out ways to combat the abrasion, clinging and overheating from dust coating.

Orbits Cross, Creating Off Planet Research

The trajectories that took Vince and Melissa to Saint Martin’s University were very different.

In 2013, Melissa came to Saint Martin’s University (SMU) straight out of a small, all-girls Catholic high school in Seattle. “I’ve always deeply loved math. In 9th grade, I had a parish priest suggest I look at engineering. That same week a friend’s mom, who had been a Boeing engineer herself, suggested the same thing.” These comments shifted Melissa’s attention to engineering as a field of study and occupation.

Besides SMU’s stellar academic record, Melissa liked the small campus feel and that there wasn’t “a street running through it.” SMU was also very generous with scholarships, ultimately allowing Melissa to finish her degree without any debt.

Vince transferred to SMU as a junior. He had spent decades in the space and aerospace industries. In 2012, he headed back to college, leaving his employer Blue Origin, to attend Highline Community College. Blue Origin is an aerospace manufacturing and spaceflight company owned by Amazon Founder and CEO Jeff Bezos.

It was during this time Vince began researching the possibility of entering the Google Lunar XPRIZE competition. Space travel was an obtainable idea for Vince. In addition to his own life experience, Vince was surrounded by aerospace growing up. His father was an electronics engineer who worked on many space projects including the Apollo program and Skylab, the United States’ first space station.

While Vince was looking further into this competition, he discovered there was a need for simulated lunar regolith (man-made Moon dust) and lunar research labs, and switched his focus. He conducted some early experiments into manufacturing the lunar simulant at his home, and in the summer of 2015 founded Off Planet Research.

Founder Vince Roux’s wife, Jill, passed away in 2014. The firm’s crest embodies her role as a scientist, benefactor and inspiration for Off Planet Research. Her bow is a compass, with the Moon backdrop depicting the starting place for this celestial-focused firm which has set its sights far beyond our lunar neighbor.

That fall Vince transferred to SMU. Like Melissa, Vince had decided on mechanical engineering, which put them in many of the same classes. They met in their fluid mechanics class, along with fellow student Jamie Widdowson.

The next year, the three leveraged their senior design project, focusing on research and development to design equipment for creating lunar simulant. By the end of fall 2016, they had successfully developed basic methods needed for making simulants.

“Unlike other’s simulant production processes that were faced with a limited budget and quick deadline, we were able to spend almost an entire year researching how to replicate the natural formation processes on the Moon, which differs greatly from those on Earth,” said Melissa. On the Moon, formation happens with micro-meteor strikes on the Moon’s surface, heating and pulverizing rocks, which contain silica and metals such as iron.

The trio continued to refine their equipment and methods, and the first samples of the lunar simulant were produced by the spring of 2017. This was a huge accomplishment and what was needed to meet the requirements of their senior project.

Upon graduation, Jamie got married and moved to Hawaii, and Melissa joined OPR as a co-owner.

Nitty-Gritty of Creating a Climate-controlled Simulation Lab

“We are constructing one of the few climate-controlled testing facilities in the world and, to our knowledge, the largest,” said Melissa. Located at Saint Martin’s University, the 700-square-foot space lab room is slowly being filled up with the lunar simulant produced by OPR.

Once OPR figured out how to create these sharp, abrasive dust-sized particles, the next hurdle was how to increase quantity and still maintain quality, said Vince. They went from being able to create 12 specks a day to about 160 grams per hour, which is about a gallon of material a day. They are working to increase their production to tons per day.

A lunar particle brought back to Earth during the Apollo missions. Note the sharp edges and how multiple

smaller particles joined together. Photo Credit: Carol Kiely

Their feedstock, the materials they crush to begin the process, is basalt and anorthosite. Twenty tons of each have been delivered to their Lacey location over the last couple years. Eighty percent of the Moon’s surface is composed of a combination of one-third basalt and two-thirds anorthosite.

But different locations on the Moon are made up of different percentages. Most simulant providers use 100 percent basalt, since it’s easier to obtain. “It’s unique to have a simulant that includes both components,” said Vince. “You also need a range of particle sizes,” he added, which OPR’s proprietary production process also achieves. “Because we make the different components of lunar simulant separately, we can replicate any location on the Moon where the soil composition is known,” Melissa said.

“We’ve had many discussions with many groups planning lunar missions in the near future,” said Vince, who is looking forward to publicly announcing clients later in 2018.

“Our focus is the success of our clients. We’re looking for long-term relationships,” said Melissa. For the near future, they have identified three main business offerings:

- Lab Rental at their Lacey location

- Simulant rental for off-site use

- Consulting

Because of OPR’s commitment to providing a consistent simulant, and the importance of that to their clients’ testing, they keep very close tabs on their product.

As the lunar simulant is used, degradation happens. Its glass-like components make it not only abrasive, but also easy to break down. This change in structure and composition can change test results. So, whether at their lab, or with rental, OPR tests the simulant during its use to ensure it maintains its integrity and that tests are reliable and comparative. If during a rental period the simulant has degraded, OPR will provide refresher batches.

Childhood Space Hero becomes a Real-life Resource

Vince, Jonette Stecklein of NASA JSC, Apollo astronaut Harrison “Jack” Schmitt, and Melissa at the LEAG Conference in October 2017. Photo Credit: Off Planet Research, LLC

“When I was in 5th grade, I remember watching an astronaut on the Moon on the black and white television at school. It was Jack Schmitt. Then I got to meet him in person at a space conference,” shared Vince. “He was so gracious and generous. It was a thrill.”

That meeting, and some conversations with Harrison “Jack” Schmitt, has been invaluable to OPR as Jack shares his personal experiences. “Jack wants to see future missions succeed,” said Vince. “He has given us input on cohesion of materials. He has real life experience with the Moon’s environment.”

Jack is the only professional geologist to have visited the Moon, and the second-to-the-last person to have stepped-off of it. In his book, Return to the Moon, he writes, “The invasive nature of lunar dust represents a more challenging engineering design issue, as well as a health issue for settlers, than does radiation.” What better person to have as an advocate for a sustainable return to the Moon.

Sharing Their Story with the World

“We like to state what we’ve already achieved, not hype what we hope to do,” said Vince. He added this is unusual in an industry full of big ideas. “People are genuinely surprised at how much OPR has actually accomplished, not just what we hope to do.”

Melissa and Vince attended their first Lunar Exploration Analysis Group (LEAG) conference in the fall of 2016. LEAG, chartered by NASA, brings together experts in the lunar industry.

A quick look at LEAG’s website makes it obvious OPR is involved in relevant work, as the home page’s first news topic is “Simulant Development and Use.”

Melissa and Vince wer

e asked to present their work at the following year’s LEAG conference. “Not only was it an honor, it spurred conversations with several groups intending to send missions to the Moon who could benefit from high-quality testing of their equipment before their missions.”

The Starry-eyed Dreams of the Founders

“The Moon is just the starting point,” said Vince. They already have plans for a larger facility with expanded capabilities. The phase two project will include enhanced climate control, with atmospheric humidity below 10%, and simulated reduced gravity.

They also excitedly talk about a variety of future opportunities from developing lunar equipment and technologies, to a Martian simulation lab, to a “Small Worlds” program, which would replicate the environments on comets, asteroids and moons of other planets.

Melissa and Vince at their second LEAG conference. Photo Credit: Off Planet Research, LLC

Help from Many Local Sources

In addition to generous industry folks, teachers and astronauts, OPR has found needed assistance with services under the umbrella at the Center for Business & Innovation (CB&I).

“Two of our biggest champions have been Kate Hoy and Christine Buckley,” said Melissa. “We are very appreciative of them.”

Kate is a contracting specialist with the Washington State Procurement Technical Assistance Center (PTAC). PTAC is a great resource for helping Off Planet navigate various government processes. Kate said, “We are able to help with preparing Small Business Innovation Research proposals, securing registrations and crafting marketing materials so OPR can reach out to prime contractors.”

Christine is a business coach with the Washington Center for Women in Business (WCWB) and she assisted with developing processes and systems related to research and development, as well as the business in general. “This includes helping them develop their business model, business plan, systems, cash flow projections, funding needs and marketing, just to name a few.”

Melissa was complementary of the assistance. “As engineers, it can be challenging to handle the business aspects of our work: creating a business plan, marketing, contracts, etc. This is an issue a lot of entrepreneurs must deal with to be successful,” said Melissa. She explained entrepreneurs are focused on and good at their product or service, but need help with the details that turn that product or service into a business.

“Kate and Christine are helping us bridge that gap by enabling us to complete those details. By combining our knowledge of our work with their knowledge of small businesses, we are able to be prepared for growing and sustaining our business.”

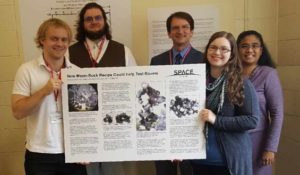

OPR is a five-person firm. From left: Contributing Researcher Aaron, Contributing Researcher Neil, Vince, Melissa and Communications Director Rebecca Mabanglo-Mayor. Photo Credit: Off Planet Research

OPR is a five-person firm. From left: Contributing Researcher Aaron, Contributing Researcher Neil, Vince, Melissa and Communications Director Rebecca Mabanglo-Mayor. Photo Credit: Off Planet Research

Lacey’s MakerSpace (maybe an inset box/aside?)

Off Planet Research showcases the very real benefit of having a MakerSpace in our community. When clients come to Lacey to test their equipment at the lunar simulation lab, their equipment may break down or they may want to make adjustments.

The Lacey MakerSpace, hoping to open by mid-2018, will have equipment, supplies, computer numerical controlled machines, 3D printers, and other tools related to metal working, woodworking tools and electronics. It is slated to be located in Zaverl Hall, near OPR.

For the local community, the do-it-yourself space will be not only for entrepreneurs who want to build prototypes and test ideas, but also for hobbyists, students and veterans. It’s for anyone to gather and make things with equipment that is typically cost prohibitive for individuals to own.

There will also be training on how to use the tools, with classrooms and a computer center also envisioned. The Lacey MakerSpace will be membership-based, much like a gym membership.

The EDC’s Center for Business and Innovation (CB&I) has adopted the Lacey MakerSpace as a formal project, with the City of Lacey and Saint Martin’s University also instrumental in moving the idea forward. For more information on how to make this project become a reality, contact EDC Director Michael Cade.